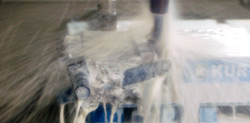

Our recycled cutting fluid is controlled chemically and biologically.

Proactive strategy

Used coolant and recycled coolant

When you use our services, our dedicated staff will consistently monitor your cutting fluid and maintain the manufacturer’s specifications to keep coolants at their peak operating condition.

Maintenance programs that are based on the condition of the fluid offer great benefits over maintenance programs that are tied to a fixed interval. Benefits include cost savings, extended tool life, and reduced downtime. This proactive approach provides your company with a major advantage over a reactive maintenance strategy.

Daily reports

We can create a daily report with the cutting fluid quality for each machine. Our record keeping makes it easy to detect problems early (like seeping machine lubricants) and keep your operations running smoothly.

Monitoring coolant concentration, pH level, tramp oil, temperature, bacteria count, water and additives ratio, liquid/solid contamination – our cutting fluid management program is the most effective way to ensure optimal performance.

Directly effects your bottom-line – almost immediately. 603-948-1181